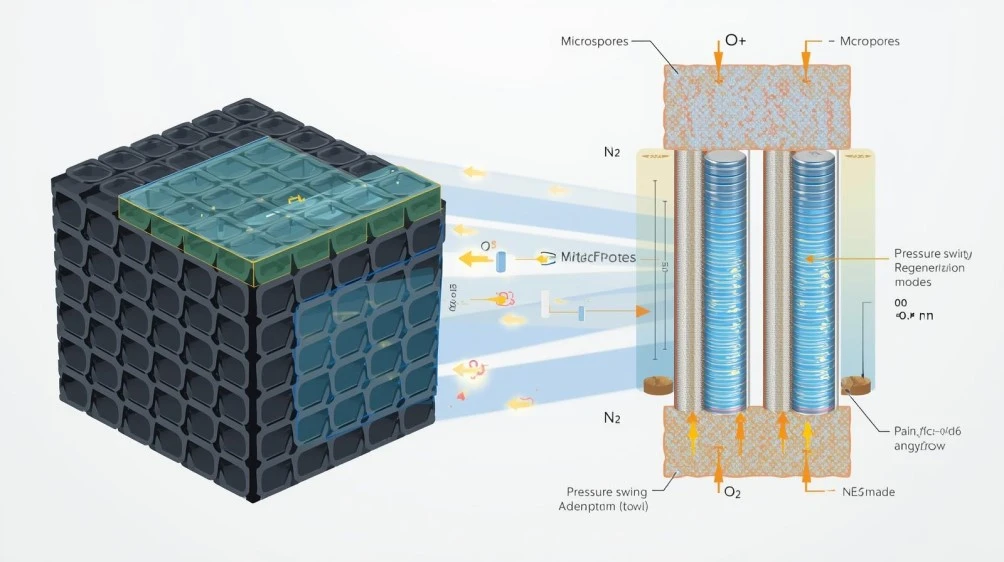

What is Carbon Molecular Sieve is a common question among industries seeking efficient solutions for high purity gas separation and nitrogen generation. Carbon molecular sieve (CMS) is a porous carbon material with a microporous structure that allows it to separate oxygen and nitrogen from air based on molecular pore sieving and kinetic diffusion. It plays a critical role in modern PSA nitrogen generator systems, delivering consistent and high purity nitrogen for various industrial applications.

At Oozechem, we supply high quality carbon molecular sieve adsorbent engineered for efficient gas separation, oxygen adsorption, and long term performance in pressure swing adsorption (PSA) systems.

Types of Carbon Molecular Sieve

At Oozechem, our CMS product range is engineered to meet different nitrogen purity, throughput, and operational stability demands. Below are key types and their distinguishing features:

CMS-220

- Designed with a uniform microporous structure and high kinetic selectivity.

- Optimized for moderate nitrogen purity levels (often 95 %+).

- Offers good mechanical strength, consistent performance, and reliable oxygen adsorption capability.

- Ideal for many standard PSA nitrogen generator applications.

CMS-240

- Engineered for higher nitrogen purity (e.g. 99 % and up) with improved oxygen / nitrogen separation performance.

- Features balanced pore distribution to maintain throughput while increasing selectivity.

- Suitable for systems operating with faster cycles and stricter purity demands.

CMS-260

- High end grade targeted at ultra high purity nitrogen applications (e.g. semiconductor, pharmaceutical).

- Exceptional cms adsorption efficiency and non polar carbon properties.

- Built for long life, excellent cms regeneration, and stable operation under variable loads.

Applications and Uses of Carbon Molecular Sieve

| Industry / Sector | Application | Purpose / Benefit |

| Food & Beverage | Modified atmosphere packaging, storage, and preservation | Extends shelf life by reducing oxygen levels |

| Electronics & Semiconductor | Nitrogen blanketing and controlled environments | Prevents oxidation and moisture damage during manufacturing |

| Chemical Processing | Nitrogen supply for reactors and storage tanks | Ensures safe, inert atmosphere and prevents unwanted reactions |

| Metallurgy & Heat Treatment | Furnace purging and protective atmosphere | Reduces scaling and oxidation of metal surfaces |

| Pharmaceutical Industry | Controlled nitrogen environments for production | Maintains product purity and quality |

| Oil & Gas Industry | Pipeline purging, well operations, and blanketing | Prevents explosions and corrosion |

| Laboratories & Research | High purity nitrogen generation for experiments | Ensures accurate and reliable results |

| Automotive Industry | Tire inflation and component manufacturing | Improves safety, stability, and performance |

| Water Treatment | Inerting and degassing systems | Enhances system safety and operational control |

How CMS Regeneration Works in PSA

The CMS regeneration process is a key part of the Pressure Swing Adsorption (PSA) system that ensures continuous and efficient nitrogen production. In the adsorption phase, clean compressed air enters the CMS bed at high pressure. Oxygen molecules are adsorbed into the microporous structure, while nitrogen passes through as the product gas.

When the CMS bed becomes saturated, the system switches to another bed to keep the process running. The saturated bed is then depressurized in the regeneration phase, releasing the trapped oxygen and restoring the adsorbent. After a quick repressurization, it’s ready for the next cycle.

Learn more about the latest advancements in CMS regeneration technology in our blog: Innovation in CMS Transforming Nitrogen Plants.

FAQs

Q1: What is Carbon Molecular Sieve used for?

A: It’s mainly used in air separation to produce high purity nitrogen for industries like food, chemical, and electronics.

Q2: How does CMS separate oxygen and nitrogen?

A: It uses molecular pore sieving — oxygen diffuses into its microporous structure faster, allowing nitrogen to pass through as the product gas.

Q3: Can CMS be regenerated?

A: Yes, cms regeneration happens during pressure swing adsorption (PSA), extending the material’s lifespan and reducing operational costs.

Q4: What makes CMS different from other adsorbents?

A: Its non polar carbon surface, microporous structure, and high adsorption capacity make it ideal for selective gas separation.

Conclusion

Carbon molecular sieve is a vital material in modern PSA nitrogen generator systems, enabling industries to separate oxygen and nitrogen efficiently and produce high purity nitrogen on demand. With its microporous structure, cms adsorption properties, and easy cms regeneration, it delivers both performance and cost savings.

Oozechem as a trusted carbon molecular sieve supplier in the UAE provides premium quality carbon molecular sieve adsorbents designed for industrial reliability and long service life.

Explore More:

- Learn more about Carbon Molecular Sieve and its features.

- Discover how CMS is used in PSA nitrogen generator systems.

- Need help choosing the right solution? Contact us for expert guidance.

- Best adsorbents in UAE