Activated carbon, also known as activated charcoal, is a highly porous filtration material made from carbon rich sources like coconut shells, coal, or wood. Thanks to its large surface area and exceptional adsorption capacity, it’s widely used in water filtration, air purification, and industrial treatment systems. In this blog, we’ll explore how activated carbon works, its different types including granular activated carbon, powdered activated carbon, extruded activated carbon, coconut shell activated carbon, and coal based activated carbon along with its key applications and benefits. At Oozechem, we offer high quality activated carbon solutions designed to meet diverse purification needs across industries.

How activated carbon works?

Unlike simple absorption, activated carbon works through adsorption. Contaminants cling to the microscopic internal pore structure of the carbon.When air or water passes through an activated carbon filter, molecules like chlorine, VOCs, odors, and organic pollutants attach to the carbon surface, leaving the output purified.

This activated carbon adsorption process is what makes it one of the most effective purification materials available.

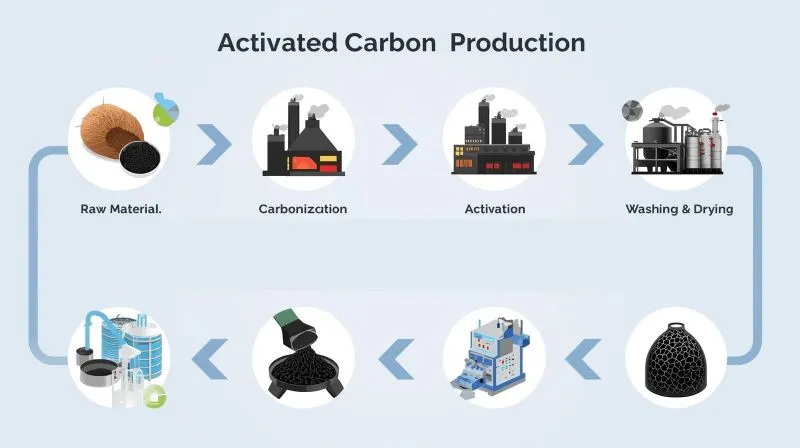

Process of Making Activated Carbon

The production of activated carbon involves several controlled steps to create its unique pore structure:

- Raw Material Selection: Typically coconut activated carbon or coal is used as feedstock.

- Carbonization: The raw material is heated in an inert atmosphere (usually 600–900 °C). Volatile components are removed, leaving behind a carbon rich char.

- Activation: The char is further heated with steam or CO₂ at 800–1100 °C to develop an extensive pore network. This step gives the material its adsorptive power.

- Washing & Drying: Residual chemicals are washed out, and the carbon is dried.

- Screening & Grading: The material is classified into granular, powdered, or extruded activated carbon according to application.

Types of Activated Carbon

1. Granular Activated Carbon (GAC)

Coarse irregular particles, excellent for continuous filtration systems. Ideal for municipal water treatment and environmental purification.

2. Powdered Activated Carbon

Fine particles designed for rapid adsorption in batch dosing systems. Common in municipal water treatment and food industries.

3. Extruded Activated Carbon

Cylindrical pellets with low dust and high mechanical strength, perfect for gas phase treatment such as VOC control and solvent recovery.

Common Activated Carbon Uses

| Application Area | Form Used | Purpose |

| Water Purification | Granular activated carbon (GAC) | Removes chlorine, odor, organic pollutants, and taste impurities |

| Municipal Water Treatment | Powdered activated carbon (PAC) | Rapid dosing to control taste, odor, and micropollutants |

| Air Purification | Extruded activated carbon | Traps VOCs, odors, and industrial emissions in air purifier systems |

| Industrial Filtration | Coal based activated carbon | Removes contaminants in chemical and petrochemical processing |

| Household Purifiers | Coconut shell activated carbon | Point of use filtration and air purifier with activated carbon filter units |

| Environmental Remediation | Mixed Grades | Groundwater cleanup, spill control, odor abatement |

| Medical & Food Industry | PAC, GAC | Decolorization, detoxification, impurity removal |

Technical Factors to Consider When Buying

- Iodine number (adsorption capacity)

- Surface area (m²/g)

- Pore size distribution (micro, meso, macro)

- Ash and moisture content

- Particle size or pellet diameter

Choosing the right grade from reliable activated carbon suppliers ensures optimal system performance.

FAQs

Q1. How does activated carbon work?

How activated carbon works is through adsorption contaminants stick to its porous surface as air or water flows through.

Q2. What is activated carbon used for?

Activated carbon used for includes water purification, air purification, solvent recovery, gold recovery, and medical treatments.

Q3. What is an activated carbon filter?

An activated carbon filter is a housing or cartridge filled with activated carbon media that removes unwanted compounds from air or water.

Q4. Which is better coconut or coal based activated carbon?

Coconut shell activated carbon offers high microporosity ideal for drinking water and air filters, while coal based activated carbon is excellent for heavy industrial applications.

Q5. Can activated carbon be regenerated?

Yes. Thermal or steam reactivation can restore its adsorption capacity, making it reusable and cost effective.

Conclusion:

Activated carbon is a highly effective adsorbent used to purify water, air, and industrial streams by trapping contaminants on its porous surface. With different types like granular activated carbon, powdered activated carbon, extruded activated carbon, coconut shell activated carbon, and coal based activated carbon, it offers flexible solutions for homes and industries. Choosing quality media from reliable activated carbon suppliers ensures efficient filtration and long lasting performance.

Explore more:

- Learn about Activated Carbon and its key properties.

- Discover different types:

- Need help choosing the right type? Contact us for expert guidance and support.

- Also Check how Activated Carbon is used in Ammonia Removal