The Gulf region’s industrial water treatment landscape demands specialized water treatment chemicals solutions to combat challenges posed by extreme heat, high salinity, and aggressive scaling conditions that accelerate equipment degradation. OozeChem, a leading chemical supplier in the UAE, understands these regional water quality demands and provides comprehensive water treatment chemicals solutions, including advanced treatment compounds that support operational efficiency, equipment longevity, and regulatory compliance across diverse industrial sectors.

Understanding Water Treatment Chemistry Fundamentals

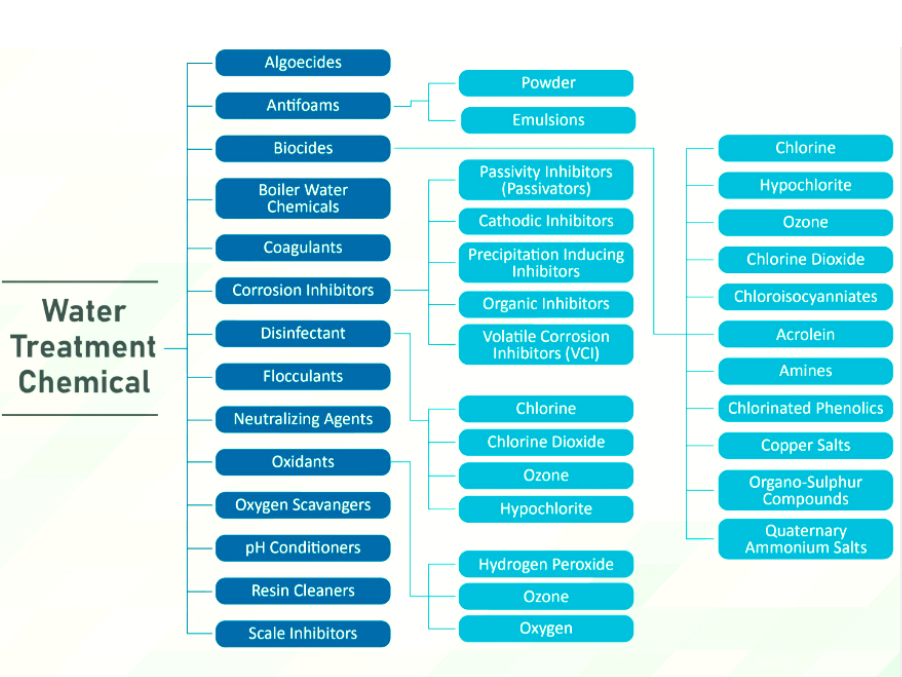

Water treatment chemicals work through various mechanisms including precipitation, coagulation, disinfection, and inhibition. These chemicals address specific water quality issues such as hardness, microbial contamination, corrosion, and scaling. The selection of appropriate chemicals depends on water source characteristics, system requirements, and intended use applications.

Modern industrial facilities require sophisticated water treatment strategies that balance effectiveness, cost efficiency, and environmental sustainability. The global water treatment chemicals market has evolved significantly, with manufacturers developing specialized formulations for specific industrial applications.

Essential Types of Water Treatment Chemicals

Coagulants and Flocculants

Coagulants such as aluminum sulfate, ferric chloride, and polyaluminum chloride neutralize suspended particles’ surface charges, enabling aggregation. Flocculants, including anionic, cationic, and nonionic polymers, bind these aggregated particles into larger flocs for easier removal through sedimentation or filtration.

These chemicals are particularly effective in treating turbid water, removing colloidal particles, and reducing total suspended solids. Industrial applications include municipal water treatment, mining operations, and manufacturing processes where water clarity is critical.

Biocides and Disinfectants

Microbiological control is essential for preventing biofilm formation, microbially influenced corrosion, and pathogen contamination. Oxidizing biocides like chlorine dioxide, sodium hypochlorite, and ozone provide broad spectrum antimicrobial activity, while non oxidizing biocides such as glutaraldehyde and isothiazolinones target specific microbial populations.

The selection between oxidizing and non oxidizing biocides depends on system compatibility, water chemistry, and target microorganisms. Many facilities implement alternating biocide programs to prevent microbial resistance development.

Scale and Corrosion Inhibitors

Scale formation occurs when dissolved minerals exceed their solubility limits, forming deposits on heat transfer surfaces and reducing system efficiency. Phosphonate based inhibitors, polymeric dispersants, and threshold inhibitors prevent scale formation by interfering with crystal growth mechanisms.

Corrosion inhibitors protect metal surfaces through filming or passivation mechanisms. Common inhibitors include phosphates, molybdates, and organic filming amines. The choice depends on metallurgy, water chemistry, and operating conditions.

Specialized Applications and Chemical Selection

Boiler Water Treatment Systems

Boiler systems require specialized chemical treatment to prevent scale formation, oxygen corrosion, and carryover. Oxygen scavengers like sodium sulfite or hydrazine remove dissolved oxygen, while alkalinity builders maintain proper pH levels. Phosphate based programs provide scale control and internal treatment for lower pressure systems.

High pressure boiler systems typically employ all volatile treatment (AVT) or combined treatment programs using volatile amines and oxygen scavengers. These systems require precise chemical control to maintain water chemistry within narrow specifications.

Cooling Tower Chemical Programs

Cooling towers concentrate dissolved solids through evaporation, creating challenging water chemistry conditions. Comprehensive treatment programs include scale inhibitors, corrosion inhibitors, biocides, and biodispersants to maintain system efficiency and prevent biological growth.

Modern cooling tower programs often incorporate environmentally friendly formulations that reduce environmental impact while maintaining performance. Multi functional inhibitors combine scale and corrosion control in single products, simplifying chemical handling and reducing costs.

Reverse Osmosis and Membrane Systems

Membrane systems require specialized pretreatment chemicals to prevent fouling and maintain flux rates. Antiscalants prevent mineral precipitation, while biocides control biological growth. Cleaning chemicals including acids, bases, and surfactants remove accumulated foulants during maintenance cycles.

The selection of RO chemicals must consider membrane compatibility, feedwater quality, and environmental discharge requirements. Many modern formulations are NSF certified for drinking water applications.

Chemical Selection Criteria and Best Practices

| Criteria | Considerations | Impact on Performance |

|---|---|---|

| Water Quality | pH, hardness, alkalinity, TDS | Determines chemical compatibility and dosage requirements |

| System Design | Open/closed loop, materials of construction | Affects chemical selection and application methods |

| Operating Conditions | Temperature, pressure, flow rates | Influences chemical stability and effectiveness |

| Environmental Factors | Discharge regulations, toxicity limits | Determines acceptable chemical types and concentrations |

| Economic Factors | Chemical costs, handling requirements | Impacts overall treatment program economics |

| Performance Goals | Efficiency targets, equipment life | Guides chemical program optimization |

Advanced Treatment Technologies and Integration

Modern water treatment increasingly incorporates advanced technologies including electrochemical treatment, membrane bioreactors, and smart monitoring systems. These technologies often work synergistically with traditional chemical treatment, enhancing overall system performance while reducing chemical consumption.

Automated chemical feed systems with real time monitoring enable precise dosing control, reducing waste and improving treatment consistency. Integration with plant control systems allows for responsive treatment adjustments based on operating conditions and water quality changes.

Regulatory Compliance and Environmental Considerations

Water treatment chemical selection must consider regulatory requirements including discharge permits, workplace safety standards, and environmental regulations. Many jurisdictions require specific certifications for chemicals used in drinking water applications or those discharged to sensitive environments.

Green chemistry initiatives have led to development of biodegradable, low toxicity formulations that maintain performance while reducing environmental impact. Life cycle assessment tools help evaluate the overall environmental footprint of treatment programs.

Future Trends in Water Treatment Chemistry

The water treatment industry continues evolving toward more sustainable, efficient solutions. Emerging trends include nanotechnology applications, bio based chemicals, and smart materials that respond to changing water conditions. These innovations promise improved performance with reduced environmental impact.

Digital transformation is revolutionizing water treatment predictive analytics, machine learning, and IoT integration. These technologies enable optimization of chemical programs based on real time data analysis and predictive modeling.

Conclusion: Optimizing Your Water Treatment Strategy

Successful water treatment requires comprehensive understanding of system requirements, water chemistry, and available chemical technologies. Working with experienced suppliers who provide technical support, training, and performance monitoring ensures optimal results while managing costs and regulatory compliance.

Regular system evaluation, water testing, and program optimization are essential for maintaining peak performance. As regulations become more stringent and sustainability becomes increasingly important, staying current with new technologies and best practices is crucial for long term success.

The investment in proper water treatment chemicals pays dividends through improved equipment reliability, reduced maintenance costs, and enhanced operational efficiency. By understanding the principles outlined in this guide, facility managers can make informed decisions that benefit both their operations and the environment.