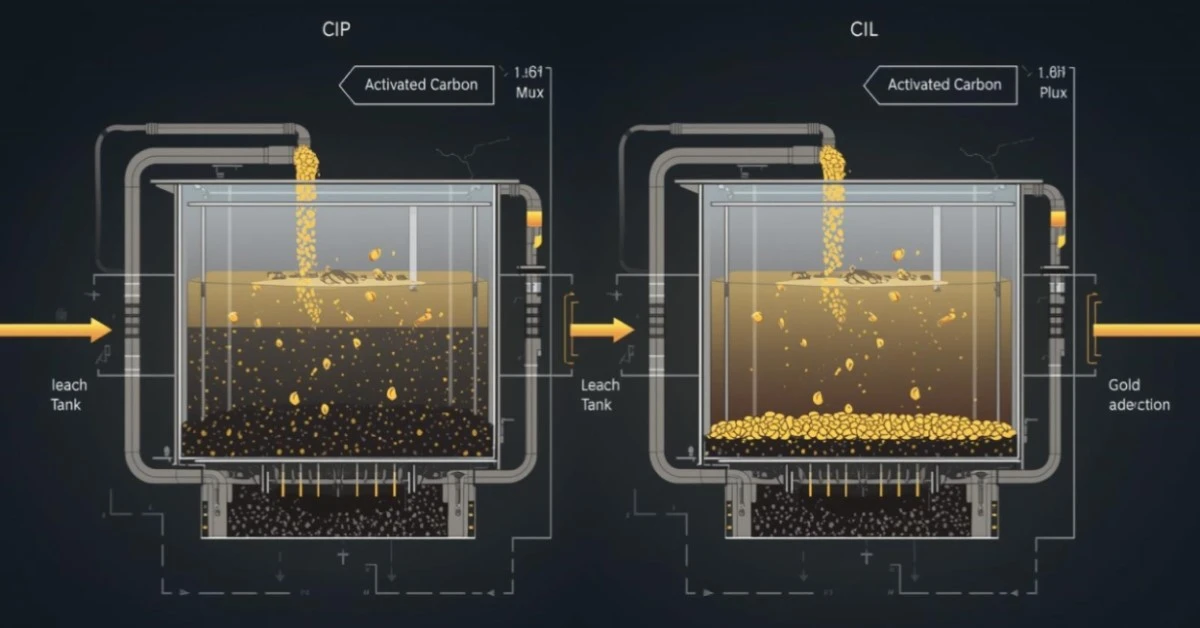

Gold recovery technologies have evolved to become more efficient and cost effective, with Carbon in Pulp (CIP) and Carbon in Leach (CIL) emerging as two of the most widely used methods in modern gold processing. Both techniques rely on activated carbon to extract gold from cyanide leached ore slurries, but they differ significantly in their process design and efficiency.

In this guide, we’ll break down the CIP vs CIL gold recovery processes, explain how each system works, and help you decide which is best for your operation.

What Is Carbon in Pulp (CIP)?

CIP Gold Recovery Process Overview

In the Carbon in Pulp (CIP) process, gold is leached from crushed ore using a cyanide solution in large leach tanks. Once the gold is in solution, activated carbon is added to the pulp in a series of tanks after leaching is complete.

How CIP Works:

- Ore is crushed and mixed with cyanide to dissolve gold into a slurry.

- After leaching, activated carbon is added to adsorb gold from the solution.

- The gold loaded carbon is separated and sent for gold recovery.

- The slurry is recycled or discarded.

Key Factors in CIP:

- Carbon particle size and hardness

- Agitation and tank design

- Slurry residence time

- Screen efficiency for carbon separation

What Is Carbon in Leach (CIL)?

CIL Gold Recovery Process Overview

Carbon in Leach (CIL) integrates leaching and adsorption into a single step. Activated carbon is added directly to the leach tanks, allowing gold to be adsorbed as it dissolves.

This approach increases efficiency by reducing gold losses that occur in intermediate transfer steps. CIL is especially advantageous for ores with slow leaching characteristics.

How CIL Works:

- Crushed ore is added to leach tanks with cyanide and activated carbon.

- Gold dissolves and is immediately adsorbed onto carbon in the same tank.

- Carbon is separated, and the gold is recovered from it.

Key Parameters in CIL:

- Cyanide concentration

- Dissolved oxygen levels

- Pulp density

- Temperature and retention time

Activated Carbon’s Role in Gold Recovery

The efficiency of both CIP and CIL systems is driven by the performance of activated carbon, typically made from coconut shell for its:

- High mechanical strength

- Excellent microporous structure

- Regenerability through thermal reactivation

Why Activated Carbon Works So Well:

- Surface area > 1000 m²/g

- High adsorption capacity for gold cyanide complexes

- Reusability through acid washing and thermal reactivation

- Improved kinetics due to surface chemistry advancements

Modern carbon formulations enhance throughput and reduce attrition losses, improving overall plant performance.

CIP vs CIL: Key Differences and Comparison

| Feature | CIP (Carbon in Pulp) | CIL (Carbon in Leach) |

|---|---|---|

| Leaching and Adsorption | Separate steps | Combined in a single tank |

| Adsorption Timing | After leaching is complete | Simultaneous with leaching |

| System Complexity | Simpler carbon handling | Requires tighter process control |

| Gold Recovery Rate | High (up to 95%) | High to very high (up to 97%) |

| Best For | Free milling ores | Refractory or slow leaching ores |

Advantages of CIP and CIL Gold Recovery Systems

- High recovery rates (often >95%)

- Scalable and flexible for various ore types

- Reduced capital and operating costs

- Lower environmental impact vs older methods (e.g., Merrill Crowe)

- Efficient carbon regeneration and reuse

- learn more about advantages of activated carbon in Gold recovery

Which System Should You Choose?

- Choose CIP if your ore has fast leaching kinetics and a simpler plant layout is preferred.

- Choose CIL for complex, refractory, or slow leaching ores where maximizing recovery is critical.

In many modern mining operations, CIL is favored due to its compact design and slightly higher recovery rates—but it does require more precise control.

Conclusion

CIP and CIL are industry leading gold recovery technologies that harness the exceptional adsorption properties of activated carbon to deliver high recovery rates, operational efficiency, and scalability in modern mining operations. Whether you choose Carbon in Pulp or Carbon in Leach, the quality of activated carbon used plays a critical role in the overall success of your gold extraction process.

Ozechem offers premium grade activated carbon specifically engineered for gold recovery applications. With Ozechem’s activated carbon, you can enhance adsorption efficiency, reduce losses, and improve the overall economics of your gold recovery operation.

Contact us today to learn more about our gold-grade activated carbon solutions.