Molecular Sieve

OozeChem is a high quality leading molecular sieve supplier in Dubai UAE, Gulf region, and worldwide, delivering reliable solutions for gas and liquid separation, air drying, and water purification. Our molecular sieve is designed for maximum efficiency, ensuring exceptional performance across industries.

Molecular sieve, also known as zeolites, are crystalline aluminosilicates with a unique structure that enables them to remove water and polar molecules due to their porous crystalline structure. Their large surface area and strong ionic interactions allow them to adsorb impurities at extremely low levels. Furthermore, they can separate gases or liquids according to size or polarity, making them valuable purification tools. Oozechem molecular sieve suppliers is a leader in synthetic molecular sieve technology, offering ultra stable options with excellent capacity retention. Our innovative manufacturing procedures provide reliability and quality, meeting the needs of a wide range of industries.

Technical Properties

Here’s a sample of the performance and physical properties you might expect:

| Parameter | Typical Range / Value |

|---|---|

| Pore Size / Aperture | 3 Å, 4 Å, 5 Å, 10 Å (for 13X) |

| Particle Size / Bead / Pellet | 1.6–2.6 mm, 2.5–5.0 mm |

| Water Adsorption Capacity | ~20–22% w/w under typical RH conditions |

| Bulk Density | ~0.60 – 0.75 g/mL |

| Attrition / Abrasion Loss | ≤ 0.2 – 0.3% |

| Regeneration Temperature | 200–300 °C (or higher depending on grade) |

| Moisture Content | ≤ 1.5% |

13X Molecular sieve

The 13X molecular sieve, derived from zeolite X in its sodium form, has substantially larger pore openings than type A crystals, with an effective pore diameter of 10 angstroms. Type 13X has the highest theoretical capacity of any common adsorbent and exceptional mass transfer rates, making it superior to type A zeolite in terms of adsorption performance. It excels at eliminating impurities that exceed the size limits of type A zeolite crystal cages. Furthermore, it is often used in nitrogen air separation processes to provide highly purified oxygen streams. Our 13X materials have strong physical properties and excellent adsorption capacities for water, alcohols, oxygenates, sulfur compounds, and carbon dioxide.

3A Molecular sieve

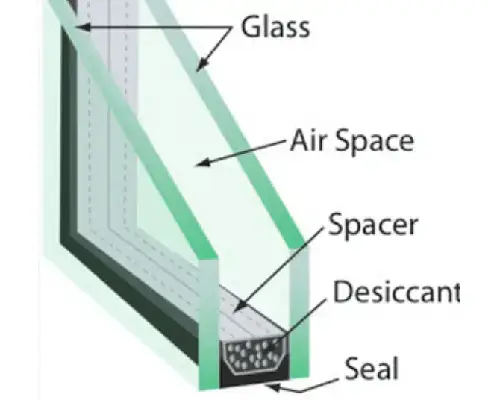

The 3A molecular sieve, an alkali metal aluminosilicate, has pore openings of about 3 angstroms. The 3A molecular sieve (which is produced via ion exchange of sodium in type 4A sieves with potassium) has high selectivity, eliminating most molecules except water. Notably, it improves crush strength, durability, and adsorption rates. This flexible bead effectively removes moisture in both liquid and gas applications. Type 3A is widely used in a variety of industries, including insulated glass production, refrigerant drying, and moisture removal. It can also be used to dry natural gas, hydrocarbon liquids, ethanol, and olefins, a reactive monomer.

4A Molecular sieve

5A Molecular sieve

Industrial Applications of Molecular Sieve

Connect With OozeChem

- +971 50 349 8566

- +971 50 349 8566

- info@oozechem.com

- B.C 1303232, C1 Building AFZ, UAE