Water is a critical component in virtually every industry—from food processing and pharmaceuticals to manufacturing and HVAC systems. The key to maintaining water quality, system longevity, and operational efficiency lies in the proper selection and use of water treatment chemicals. Whether you’re managing a cooling tower, boiler system, or wastewater unit, choosing the right chemical treatment is essential for meeting both performance and compliance goals.

In this guide, we’ll break down how to select the best chemical for water treatment based on your application, industry requirements, and local environmental regulations.

Understanding Your Water System Requirements

Before selecting any chemical water treatment, you must first understand the parameters of your water system. This includes:

- Water source (municipal, well, seawater, etc.)

- Contaminant profile (presence of hardness, metals, organics)

- System type (open-loop, closed-loop, high-pressure)

- End-use (boiler feed, cooling towers, drinking water, discharge)

A comprehensive water analysis will guide you in choosing the most effective water treatment chemicals for your needs.

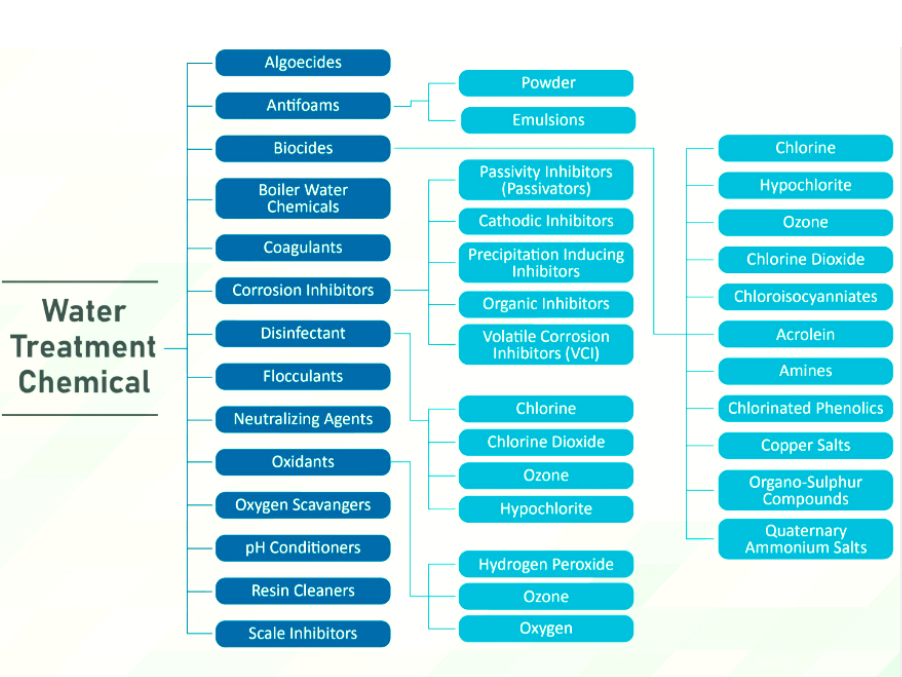

Types of Water Treatment Chemicals and Their Uses

1. Boiler Water Treatment Chemicals

Boilers are vulnerable to scale, corrosion, and fouling. To protect them, industries use a blend of chemicals such as:

- Oxygen scavengers

- Scale inhibitors

- Alkalinity builders

- Condensate line treatments

Choosing the right boiler water treatment chemicals ensures heat transfer efficiency and extends equipment life.

2. Cooling Tower Water Treatment Chemicals

Cooling towers are prone to biofilm formation, scaling, and corrosion. Effective chemical treatment of cooling tower water typically includes:

- Biocides

- Scale and corrosion inhibitors

- Dispersants

These cooling tower water treatment chemicals help maintain thermal performance and reduce energy costs.

3. Industrial Water Treatment Chemicals

Industrial processes may require specialized solutions like:

- Coagulants and flocculants

- Defoamers

- Antiscalants

- pH adjusters

These chemicals are vital for operations in oil refineries, steel plants, food processing, and chemical manufacturing.

4. Drinking and Potable Water Treatment Chemicals

For drinking water, safety is paramount. Common chemicals include:

- Disinfectants like calcium hypochlorite

- Coagulants like alum

- Activated carbon for odor and taste control

Explore Activated Carbon Products

Choosing Based on Manufacturer and Quality Standards

When evaluating water treatment chemical companies, look for those adhering to ISO standards, with full product traceability and documentation. Global brands like Veolia water treatment chemicals set benchmarks, but local sourcing from reliable water treatment chemicals manufacturers can be more economical and accessible.

The Importance of Correct Dosing and Feed Systems

No matter how effective the chemical, incorrect dosing can cause system imbalance or failure. Investing in chemical feed pumps for water treatment ensures precise, automated delivery and reduces chemical waste.

Partnering with a Trusted Distributor

A knowledgeable distributor doesn’t just sell products; they provide support, consultation, and customized solutions.

Oozechem is a leading water treatment chemical distributor in the UAE, offering high-quality chemicals for boilers, cooling towers, and industrial systems.

Learn more about water treatment chemical distributors at Oozechem

Final Checklist for Choosing the Right Chemicals

- Conduct water analysis

- Understand your system’s pressure, flow, and materials

- Select chemicals suitable for your specific contaminants and goals

- Ensure supplier compliance with international standards

- Use dosing systems for consistent application

- Partner with an expert distributor for long-term support

Recommended Products to Start With:

Choosing the right water treatment chemicals is not just about product selection—it’s about system performance, cost efficiency, and regulatory compliance. With the right partner and proper chemical strategy, you can extend asset life, reduce downtime, and ensure water safety across any application.